By Brian Orlotti

Made in Space (MIS), a Silicon Valley-based start-up that built a zero-gravity 3D printer installed on the International Space Station (ISS) four months ago, says the first set of objects is complete and the preliminary results are good.

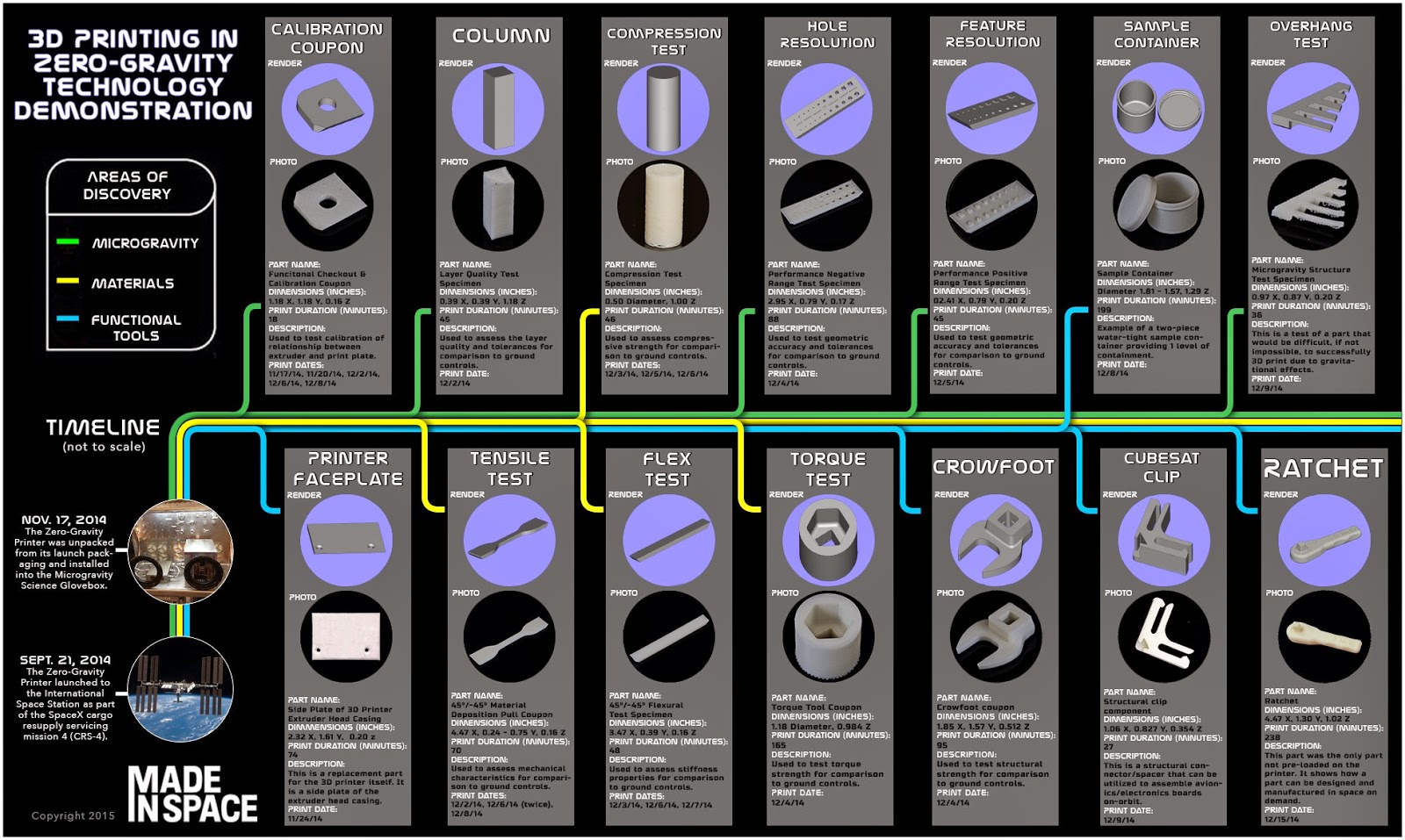

According to a Jan 27th, 2015 Made in Space blog post, "3D Printing In Space: Four Months In," the printer created fourteen unique objects over the course of the experiment.

These ranged from objects designed to test the printer's accuracy at creating features like holes and overhangs, to a part for the 3D printer itself (a faceplate), to an actual working tool: a small ratchet. The ratchet's design file was even emailed to the ISS to be printed; the first time in history that this has been done in space.

The printed objects will be brought back to Earth later this year and sent to the NASA Marshall Space Flight Centre in Alabama for analysis and stress testing.

The use of 3D printing technology in space, though still in its earliest stage, is poised to make a big impact. Space-based 3D printers would give astronauts the ability to manufacture tools and components on-site without needing to bring them along, with significant savings on space, weight and fuel.

In addition, the ability to manufacture objects in space would give astronauts greater options in unforeseen situations like malfunctions and accidents. In a sign of the technology's potential, the US Navy is also experimenting with 3D printers, installing them on combat ships to see if they can be used to produce tools, components and weapons.

MIS was founded in August 2010 by Aaron Kemmer, Jason Dunn, Mike Chen, and Michael Snyder, who all met while taking part in the graduate studies program at Singularity University (SU), a private, unaccredited learning institution/space start-up accelerator located at the NASA Ames Research Centre in Moffett Field, California.

Also located at Moffett Field, MIS was one of the first startups to emerge from SU. MIS' goal is “enabling humanity’s future in space,” by developing additive manufacturing (i.e. 3D printing) technology for use in the space environment. By creating an additive manufacturing capability in space, MIS seeks to accelerate and expand space development.

The emailing of an object to a space station for manufacture in orbit, which would have seemed the most Star Trekkian of fantasies 20 years ago, is now reality.

Made in Space (MIS), a Silicon Valley-based start-up that built a zero-gravity 3D printer installed on the International Space Station (ISS) four months ago, says the first set of objects is complete and the preliminary results are good.

|

| Graphic showing the parts that were printed as part of the 3D printing in zero gravity technology demonstration. Graphic c/o Made in Space. |

According to a Jan 27th, 2015 Made in Space blog post, "3D Printing In Space: Four Months In," the printer created fourteen unique objects over the course of the experiment.

These ranged from objects designed to test the printer's accuracy at creating features like holes and overhangs, to a part for the 3D printer itself (a faceplate), to an actual working tool: a small ratchet. The ratchet's design file was even emailed to the ISS to be printed; the first time in history that this has been done in space.

The printed objects will be brought back to Earth later this year and sent to the NASA Marshall Space Flight Centre in Alabama for analysis and stress testing.

The use of 3D printing technology in space, though still in its earliest stage, is poised to make a big impact. Space-based 3D printers would give astronauts the ability to manufacture tools and components on-site without needing to bring them along, with significant savings on space, weight and fuel.

In addition, the ability to manufacture objects in space would give astronauts greater options in unforeseen situations like malfunctions and accidents. In a sign of the technology's potential, the US Navy is also experimenting with 3D printers, installing them on combat ships to see if they can be used to produce tools, components and weapons.

MIS was founded in August 2010 by Aaron Kemmer, Jason Dunn, Mike Chen, and Michael Snyder, who all met while taking part in the graduate studies program at Singularity University (SU), a private, unaccredited learning institution/space start-up accelerator located at the NASA Ames Research Centre in Moffett Field, California.

Also located at Moffett Field, MIS was one of the first startups to emerge from SU. MIS' goal is “enabling humanity’s future in space,” by developing additive manufacturing (i.e. 3D printing) technology for use in the space environment. By creating an additive manufacturing capability in space, MIS seeks to accelerate and expand space development.

The emailing of an object to a space station for manufacture in orbit, which would have seemed the most Star Trekkian of fantasies 20 years ago, is now reality.

|

| Brian Orlotti. |

In the coming decades, we might gaze in wonder at 3D-printed solar arrays, space stations and spaceships; more science fiction marvels brought to life.

____________________________________________________________

Brian Orlotti is a network operations centre analyst at Shomi, a Canadian provider of on-demand internet streaming media and a regular contributor to the Commercial Space blog.

Brian Orlotti is a network operations centre analyst at Shomi, a Canadian provider of on-demand internet streaming media and a regular contributor to the Commercial Space blog.

No comments:

Post a Comment